Scan the code to enter the product selection mini-program.

Liquid Lens

Measuring Inner Wall Lens

Measuring Outer Wall Lens

Multi-angle Lens

Oblique Lens

High Performance Internal Coaxial Telecentric Lens

Ring Light

Bar Light

Coaxial Light

Back Light

Dome Light

Telecentric Light

Spot Light

Parallel Focus Light

High Bright Line Light

Plane Shadowless Light

Square Shadowless Light

Needle Inspection Light

Arch-shaped Light

Structural Light

Scan the code to enter the product selection mini-program.

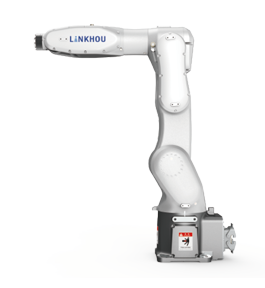

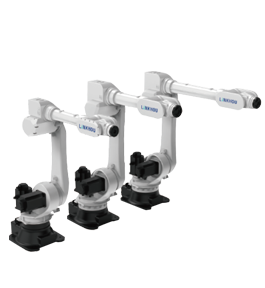

AMR needs to transport raw materials (CELL, PCB, bracket A, bracket B, upper cover, shell, etc.) from the raw material warehouse to the workshop cache. When the production line is short of materials, the raw materials (CELL, PCB, bracket A, bracket B, upp

AMR needs intelligent scheduling through the 1.2m channel, multi-vehicle operation is not congested, and at the same time, it needs to avoid personnel pulling manual hydraulic vehicles through to complete orderly operation.

There is a large flow of people on site, especially during commuting and rest periods, AMR needs to intelligently find the best path to efficiently complete material transfer.

AMR and personnel share the same air shower door, and it is necessary to safely pass through the air shower door in the case of possible manual intervention to ensure the efficient operation of materials.

The material is controlled by the system, which automatically monitors the material condition at the line edge, triggers the generation task, and opens the Pack line material handling unmanned.